Page 63 - British and Metric Catalog

P. 63

Technical Data Technical Data

HYDRAULIC HOSE

.com ® HYDRAULIC HOSE

.com ®

How to ID 24° Tube Fittings How to ID 24° Tube Fittings (cont.)

24° tube fittings, or ‘Bite-Type,’ are the most popular fitting globally and employ the most advanced tube fitting system in the Pressure Classes

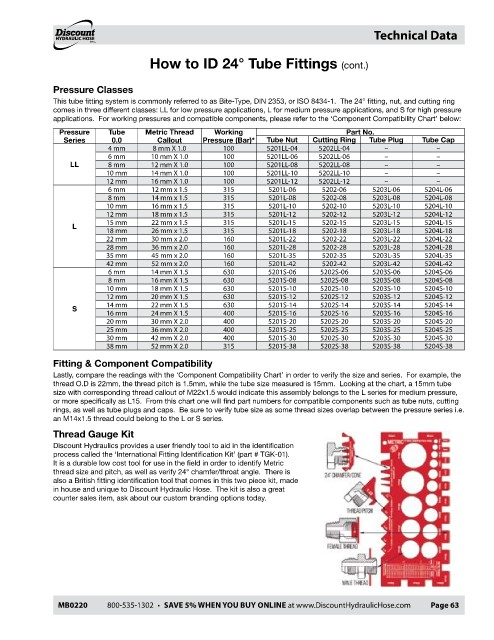

world. This system is capable of withstanding high pressures and extreme vibration, thanks to the cutting ring design. The This tube fitting system is commonly referred to as Bite-Type, DIN 2353, or ISO 8434-1. The 24° fitting, nut, and cutting ring

cutting ring is a ferrule that incorporates sharp cutting edges. When a nut is torqued onto the fitting, the base of the nut comes comes in three different classes: LL for low pressure applications, L for medium pressure applications, and S for high pressure

into contact with the cutting ring, wedging it into the 24° tapered throat of the fitting thereby cutting into and gripping the tube. applications. For working pressures and compatible components, please refer to the ‘Component Compatibility Chart’ below:

Identify with caution, DIN fittings employ Metric threads and closely resemble other Metric fittings.

Pressure Tube Metric Thread Working Part No.

Series 0.0 Callout Pressure (Bar)* Tube Nut Cutting Ring Tube Plug Tube Cap

4 mm 8 mm X 1.0 100 5201LL-04 5202LL-04 – –

6 mm 10 mm X 1.0 100 5201LL-06 5202LL-06 – –

LL 8 mm 12 mm X 1.0 100 5201LL-08 5202LL-08 – –

10 mm 14 mm X 1.0 100 5201LL-10 5202LL-10 – –

12 mm 16 mm X 1.0 100 5201LL-12 5202LL-12 – –

6 mm 12 mm x 1.5 315 5201L-06 5202-06 5203L-06 5204L-06

8 mm 14 mm x 1.5 315 5201L-08 5202-08 5203L-08 5204L-08

24° Throat Angle 10 mm 16 mm x 1.5 315 5201L-10 5202-10 5203L-10 5204L-10

18 mm x 1.5

5204L-12

315

5202-12

5203L-12

5201L-12

12 mm

The fitting itself incorporates a 24° tapered throat adjacent to the L 15 mm 22 mm x 1.5 315 5201L-15 5202-15 5203L-15 5204L-15

tube receptacle (where the tube ‘bottoms out’), which guides the 18 mm 26 mm x 1.5 315 5201L-18 5202-18 5203L-18 5204L-18

wedging of the cutting ring while the nut provides torque. Proper 22 mm 30 mm x 2.0 160 5201L-22 5202-22 5203L-22 5204L-22

attention must be given to the relevant installation instructions in 28 mm 36 mm x 2.0 160 5201L-28 5202-28 5203L-28 5204L-28

order to achieve a properly sealed assembly. Refer to the Assembly 35 mm 45 mm x 2.0 160 5201L-35 5202-35 5203L-35 5204L-35

Instructions for details. 42 mm 52 mm x 2.0 160 5201L-42 5202-42 5203L-42 5204L-42

6 mm 14 mm X 1.5 630 5201S-06 5202S-06 5203S-06 5204S-06

Styles and Variations 8 mm 16 mm X 1.5 630 5201S-08 5202S-08 5203S-08 5204S-08

There are numerous variations of cutting rings available, as well as 10 mm 18 mm X 1.5 630 5201S-10 5202S-10 5203S-10 5204S-10

12 mm

5202S-12

20 mm X 1.5

5201S-12

5204S-12

5203S-12

630

mating styles incorporating swivel nuts, tube nipples and/or hose 14 mm 22 mm X 1.5 630 5201S-14 5202S-14 5203S-14 5204S-14

ends that replace the cutting ring in order to provide a seal. The latter S 16 mm 24 mm X 1.5 400 5201S-16 5202S-16 5203S-16 5204S-16

versions do not require assembly by means of torquing the tube nut as 20 mm 30 mm X 2.0 400 5201S-20 5202S-20 5203S-20 5204S-20

the flare is already incorporated into the tube or hose. However, the 25 mm 36 mm X 2.0 400 5201S-25 5202S-25 5203S-25 5204S-25

24° fitting and nut remain consistent throughout the varying styles. 30 mm 42 mm X 2.0 400 5201S-30 5202S-30 5203S-30 5204S-30

38 mm 52 mm X 2.0 315 5201S-38 5202S-38 5203S-38 5204S-38

Fitting & Component Compatibility

How to identify 24° Metric Tube Fittings Lastly, compare the readings with the ‘Component Compatibility Chart’ in order to verify the size and series. For example, the

The first step is to look for a size and series listed on the nut itself. It should list something like LL-08, 18-L, S20 or similar. thread O.D is 22mm, the thread pitch is 1.5mm, while the tube size measured is 15mm. Looking at the chart, a 15mm tube

Once identified, refer to the ‘Component Compatibility Chart’ above for information on relevant components such as cutting size with corresponding thread callout of M22x1.5 would indicate this assembly belongs to the L series for medium pressure,

rings, plugs, and caps. Not all manufacturers list this information on the nut, so further steps might be required. or more specifically as L15. From this chart one will find part numbers for compatible components such as tube nuts, cutting

rings, as well as tube plugs and caps. Be sure to verify tube size as some thread sizes overlap between the pressure series i.e.

Determining Size & Series Manually an M14x1.5 thread could belong to the L or S series.

If no sizing information is available on the nut, the next step is to take a caliper reading

of the outer diameter (O.D) of the tube or the inner diameter (I.D) of the tube receptacle Thread Gauge Kit

inside the fitting. Be sure to set your calipers to millimeters (mm) as this is the unit of Discount Hydraulics provides a user friendly tool to aid in the identification

measurement all Metric tube fittings and the subsequent dash size system is based on. process called the ‘International Fitting Identification Kit’ (part # TGK-01).

Note this measurement for later use. It is a durable low cost tool for use in the field in order to identify Metric

thread size and pitch, as well as verify 24° chamfer/throat angle. There is

The next step is to identify the thread size also a British fitting identification tool that comes in this two piece kit, made

and pitch. To identify thread size on a metric in house and unique to Discount Hydraulic Hose. The kit is also a great

thread, simply take a caliper reading of the outer diameter (O.D) of the threads. With counter sales item, ask about our custom branding options today.

metric threads, the O.D reading directly translates to thread size (i.e. an outer diameter

reading of 22.05mm equates to a 22mm thread). To identify the thread pitch, there are

two options: a) use a caliper to measure the distance between thread crests (in mm),

or b) use a thread pitch gauge, which is recommended in order to avoid false identifi-

cation. Thread pitches in the 24° DIN tube fitting class are 1.0mm, 1.5mm, or 2.0mm.

The thread size and pitch are then combined to form the ‘thread callout’, which could

be displayed as M22x1.5 or 22mm x 1.5, etc.

Page 62 800-535-1302 • SAVE 5% WHEN YOU BUY ONLINE at www.DiscountHydraulicHose.com MB0220 MB0220 800-535-1302 • SAVE 5% WHEN YOU BUY ONLINE at www.DiscountHydraulicHose.com Page 63