Page 64 - British and Metric Catalog

P. 64

Technical Data Technical Data

HYDRAULIC HOSE

.com ® HYDRAULIC HOSE

.com ®

How to Assemble 24° DIN Tube Fittings How to order 24° DIN Tube Fittings from Discount Hydraulic

1. The first step in assembly is to cut the tube to length, then de-burr and clean. Cut tubing with appropriate saw only. To order 24° DIN tube fittings from Discount Hydraulic Hose it is important to understand the part number system. This system

is typical of most manufacturers:

2. Next, pre-set the cutting ring by initiating the bite into the tube. There are two ways to complete the pre-set: either a)

manually with a fitting or hardened pre-assembly fitting body, or b) with a hydraulic pre-set machine. Hydraulic pre-setting 1. The first four numbers indicates the part series i.e. 5000 is a male DIN union.

is recommended for assemblies with tube size greater than 18mm. 2. The pressure class (LL, L, or S) is indicated at the end of the series number i.e 5000L, 5002S, 5063LL, etc.

3. Perform pre-set inspection to verify proper installation of cutting ring. 3. For instances where a DIN x DIN fitting does not have a jump size, only one dash size is displayed. For example, a 5000L-

4. Install the assembly. 06 is a light duty L06 x L06 DIN union.

4. The dash numbers indicate tube size when describing the DIN side of the fitting. From the last example, a 5000L-06 is

Manual Pre-set Method an L06 indicating a M12x1.5 thread with 6mm tube receptacle; see the ‘Component Compatibility Chart’ in the How to

To manually pre-set the cutting ring you will need either the fitting or a hardened pre-assembly fitting body. Hardened pre- Assemble 24° DIN Tube Fittings section for details on tube size & thread size relationship.

assembly bodies are recommended for higher volume jobs, or when using Stainless Steel tube or standpipe fittings. 5. For non-DIN threads such as NPT, BSPP, etc., the regular dash system is used i.e. -08 indicates 1/2”, -12 is 3/4”, etc.

Ask Discount Hydraulic Hose for details. Discount Hydraulic Hose usually displays dash sizes with tube or hose side first, then port side.

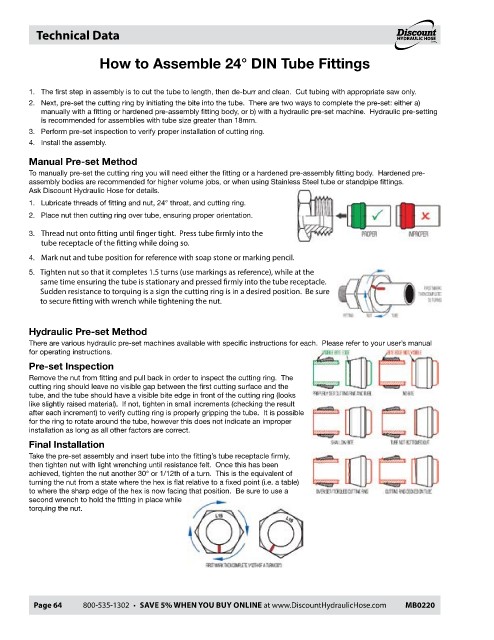

1. Lubricate threads of fitting and nut, 24° throat, and cutting ring.

6. To order a complete DIN assembly (including fitting, cutting ring, and nut) simply add a “C” to the end of the part number.

2. Place nut then cutting ring over tube, ensuring proper orientation. For example, a complete L06 male DIN union assembly would be 5000L-06C, etc. Please note that all LL series (extra

light duty) parts come complete. When a complete assembly is ordered from Discount Hydraulic Hose, there is no need to

3. Thread nut onto fitting until finger tight. Press tube firmly into the identify components to go along with your assembly. Discount Hydraulic Hose will complete the necessary steps to ensure

tube receptacle of the fitting while doing so. you are provided with compatible components.

4. Mark nut and tube position for reference with soap stone or marking pencil. Example:

Shown below in black only is 5158L-22-22-12: Male DIN X Male BSPP adjustable Run

5. Tighten nut so that it completes 1.5 turns (use markings as reference), while at the Tee, size L22 for the DIN threads, and dash size 12 BSPP (3/4”). When ordered as

same time ensuring the tube is stationary and pressed firmly into the tube receptacle. part number 5158L-22-22-12C it comes as a complete assembly with cutting rings

Sudden resistance to torquing is a sign the cutting ring is in a desired position. Be sure and nuts for the two L22 Male DIN threads (components shown in green). Looking at

to secure fitting with wrench while tightening the nut. the ‘Component Compatibility Chart’ in the How to Assemble 24° DIN Tube Fittings

section, one would notice the compatible nuts for this assembly would be 5201L-22

with the compatible cutting rings being 5202-22.

Hydraulic Pre-set Method

There are various hydraulic pre-set machines available with specific instructions for each. Please refer to your user’s manual

for operating instructions.

Pre-set Inspection

Remove the nut from fitting and pull back in order to inspect the cutting ring. The

cutting ring should leave no visible gap between the first cutting surface and the

tube, and the tube should have a visible bite edge in front of the cutting ring (looks

like slightly raised material). If not, tighten in small increments (checking the result

after each increment) to verify cutting ring is properly gripping the tube. It is possible

for the ring to rotate around the tube, however this does not indicate an improper

installation as long as all other factors are correct.

Final Installation

Take the pre-set assembly and insert tube into the fitting’s tube receptacle firmly,

then tighten nut with light wrenching until resistance felt. Once this has been

achieved, tighten the nut another 30° or 1/12th of a turn. This is the equivalent of

turning the nut from a state where the hex is flat relative to a fixed point (i.e. a table)

to where the sharp edge of the hex is now facing that position. Be sure to use a

second wrench to hold the fitting in place while

torquing the nut.

Page 64 800-535-1302 • SAVE 5% WHEN YOU BUY ONLINE at www.DiscountHydraulicHose.com MB0220 MB0220 800-535-1302 • SAVE 5% WHEN YOU BUY ONLINE at www.DiscountHydraulicHose.com Page 65